Pipe Gallery Trolley

Pipe gallery trolley is a tunnel built underground in a city, integrating various engineeringpipe gallerys such as electric power, telecommunication, gas, heat and water supply and drainage system. There is special inspection port, lifting port and monitoring system, and planning, design, construction and management for the whole system have been consolidated and implemented. It is an important infrastructure and lifeline for a city's running and management. To suit the market need, our company has developed the TC-120 pipe gallery trolley system. It is a new model trolley which ergonomically integrates the formwork system and trolley into a unity. The formwork can be installed and removed easily by adjusting the spindle strut of the trolley, without disassembling the whole system, thus achieving a safe and quick construction rationale.

The trolley system is divided into semi-automatic traveling system and fully automatic traveling system.

1.Semi-automatic traveling system : The trolley system consists of gantry, formwork support system, hydraulic lifting system, adjustment support and traveling wheel. It needs to be dragged forward by a pulling device such as a hoist.

2.Fully-automatic traveling system: The trolley system consists of gantry, formwork support system, hydraulic lifting system, adjustment support and electric traveling wheel. It only needs to press the button to move forward or backward.

1.The pipe gallery trolley system transmits all the loads generated by the concrete to the trolley gantry through the support system. The structure principle is simple and the force is reasonable. It has the characteristics of large rigidity, convenient operation and high safety factor.

2.The pipe gallery trolley system has a large operating space, which is convenient for workers to operate and related personnel to visit and inspect.

3.Quick and easy to install, fewer parts required, not easy to lose, easy to clean on site

4.After one-time assembly of the trolley system, there is no need to disassemble and it can be put into recyclable use.

5.The formwork of pipe gallery trolley system has the advantages of short erection time (according to the specific situation of the site, the regular time is about half a day), less personnel, and long-term turnover can reduce the construction period and cost of manpower as well.

1.Material checking

After entering the field, check the materials to ensure that the materials are consistent with the purchase list.

2.Site preparation

Before installing the TC-120 pipe gallery trolley system, the bottom of the pipe and the guide walls on both sides should be poured in advance (the formwork needs to be wrapped 100mm)

3.Installation of bottom stringer

The adjustment support, the traveling wheel and the hydraulic lifting system are connected to the bottom stringer. Place the traveling trough according to the drawing mark ([16 channel steel, prepared by site), and extend the adjustment support beyond the hydraulic lifting system and the traveling wheel, install the connected bottom stringer. As shown below:

3.Installation of bottom stringer

The adjustment support, the traveling wheel and the hydraulic lifting system are connected to the bottom stringer. Place the traveling trough according to the drawing mark ([16 channel steel, prepared by site), and extend the adjustment support beyond the hydraulic lifting system and the traveling wheel, install the connected bottom stringer. As shown below:

4.Mounting gantry

Connect the door handle to the bottom stringer. As shown below:

5.Installation of top stringers and formwork

After Connecting the gantry to the top stringer, then connect the formwork . After the side formwork being installed and adjusted, the surface should be smooth and flat, the joints are free of faults, and the geometric dimensions meet the design requirements. As shown below:

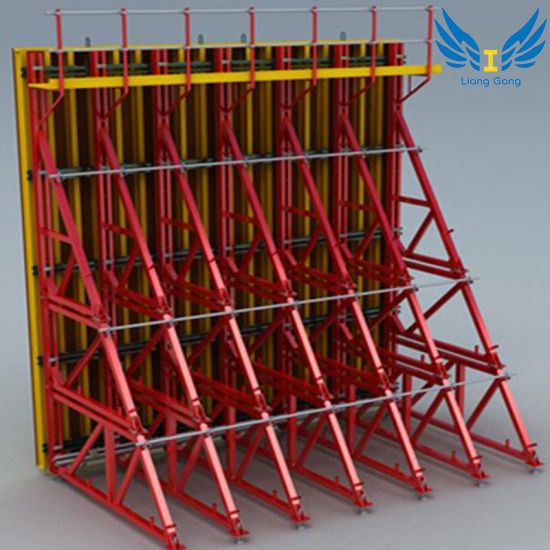

6.Installation of the formwork support

Connect the cross brace of the formwork with the diagonal brace of the gantry to the formwork. As shown below:

7.Installation of motor and circuit

Install hydraulic system motor and electric traveling wheel motor, add 46# hydraulic oil, and connect the circuit. As shown below:

8.Testing

After the first installation, the pipe gallery trolley system must be tested, and used after testing.

Testing items:

(1)Whether the hydraulic lifting system and the electric traveling wheel motor rotate normally;

(2)Whether the hydraulic lifting system cylinder is working properly;

(3)Whether the hydraulic cylinder and hydraulic pipe leak oil;

(4)Whether the electric traveling wheel is normal when walking;

9.Acceptance

After the pipe gallery trolley system is properly tested, it is reported to the user for acceptance. After the acceptance is passed, the two parties sign the form and put it into use.

Project application of pipe gallery trolley

Packing & Delivery

Packing Details : Package Box, Steel Pallet, Steel frame, Container.

Delivery Details : Generally it is 5-30 days, it is according to quantity.

Port: Shanghai

1.Consulting,Design,and Quotation

Offer you a general idea of formwork & scaffold among LiangGong various systems, to fit your project demand.

Design and Customized forming & shoring proposal according to your structural drawing by Auto-CAD.

2.Manufacture and Quality Inspection

Large-scale production workshop and First-class production line, as well as a professional quality inspection team, which will provide you with high quality standard products.

Test report will be available according to different norms from different regions in order to offer no worries to clients or meet destination authority requirements.

3.Packing and Shipment

From fabrication to loading, use standard export packages to get to your site quickly.

4.Remote or On-site instruction

If you have any questions, we can provide remote or on-site guidance. Our aim is to make customers feel at ease and satisfied throughout the process.

Lianggong Formwork Co., Ltd. is one of the leading formwork and scaffolding companies headquartered in Nanjing City, China, with its factories located in Jianhu Economic Development Zone of Yancheng City, Jiangsu Province. As a well-established company in construction formwork field, Lianggong has been devoted itself and specialized in formwork and scaffolding research, development, manufacturing, and labor service.

During the years of hardworking since 2010 by the whole company staff, Lianggong has successfully delivered and served a large number of projects at home and abroad, such as bridges, tunnels, power stations, and industrial & civil constructions. Major products of Lianggong include H20 timber beam, wall and column formwork, single-sided bracket, crane-lifted climbing formwork, hydraulic auto-climbing system, protection screen and unloading platform, shaft beam, table formwork, ring-lock scaffolding and stair tower, cantilever forming traveller and hydraulic tunnel lining trolley, etc.

Utilizing its strong technical background and abundant engineering experience, and always bearing in mind to keep its cost-effectiveness and efficiency for clients, Lianggong will continue to be your best partner in any project from the very start and achieve higher and further goals together.

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-15 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

China Cantilever Climbing Formwork for Core Wall

China Cantilever Climbing Formwork for Core Wall China Lianggong Table Shuttering Plates Plywood

China Lianggong Table Shuttering Plates Plywood  China Lianggong Single-Side Brace for Subway Con

China Lianggong Single-Side Brace for Subway Con China Construction Climbing Formwork for Bridge

China Construction Climbing Formwork for Bridge  China Highly Efficient Slab Table Formwork Syste

China Highly Efficient Slab Table Formwork Syste